Launch and Ramp-up management encompasses a set of strategies and processes aimed at smoothly transitioning from the prototyping and testing phases to full-scale production

Launch and Ramp-up management is a critical phase that bridges the gap between the development and production which demands careful planning, coordination, and execution.

The ramp-up phase is a make-or-break moment, as it directly impacts competitiveness, profitability, and reputation. Efficient ramp-up management can result in shorter time-to-market, reduced production costs, and higher quality, giving manufacturers a significant edge in the market.

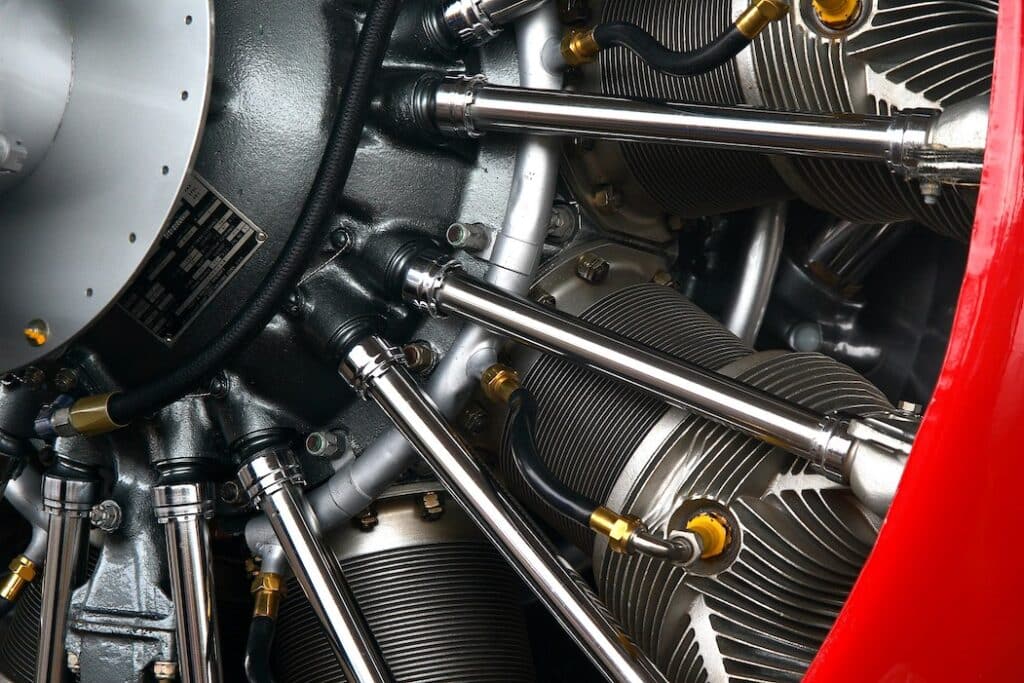

The automotive industry, known for its highly competitive nature, faces unique challenges during ramp-up due to the complexity of modern vehicles, stringent quality standards, and ever-evolving consumer preferences. An integral part of this is the management of supplies, where product quality and timing issues frequently occur.

The challenges are significant, but with the right strategies and technologies, companies can maximize efficiency and ensure a successful transition from development to full-scale production.

Modern supply chains are intricate, involving thousands of suppliers providing components and subsystems.

Coordinating these suppliers during ramp-up can be challenging, as any disruptions can cascade through the production process.

This complexity requires meticulous planning and risk mitigation strategies.

We can provide you with industry specialists and A-level management resources to steer you project in the right direction and ensure you realize critical objectives along the way.

Building strong relationships with key suppliers and involving them in the ramp-up process can lead to better communication, early issue detection, and collaborative problem-solving.

Our expert team ensures the focus that is needed for the exceptional challenges. A successful ramp-up incorporates the entire value chain, which is why we can also use our quality and supply management to always ensure a consistent assessment of upstream process steps outside your own direct area of influence.

Ongoing ramp-up of production is behind schedule. Missing experience in the application of new technologies in serial manufacturing and the low availability of the new equipment led in delays of deliveries. Commitments can not be kept. OEMs claim a lack of predictability and have already shown up with resident engineers. Customers are growing increasingly impatient. Limited capacity to handle the crises communication and conflicts. Additionally, staff is unexperienced in communicating with OEMs.

Strengthen our partner with dedicated OEM Task Force Managers during Ramp Up phase of Gigafactory.

General Manager Germany

Kristijan has 30 years of international experience in operational performance improvement covering Automotive, Machinery and Automation.

Core competencies: Operational Performance Improvement, Digital Transformation, Turnaround

© 2024 Orban Consulting – Designet af Aveo web&marketing

You have questions, need further information, wish to talk with us or have a completely different request? Do not hesitate to call us or send us a message via the contact form below. We look forward to hearing from you!

Fields marked with * are mandatory

We use cookies to optimize our website and our service.

You have questions, need further information, wish to talk with us or have a completely different request? Do not hesitate to call us or send us a message via the contact form below. We look forward to hearing from you!